HOT TUB COVER LIFTER!

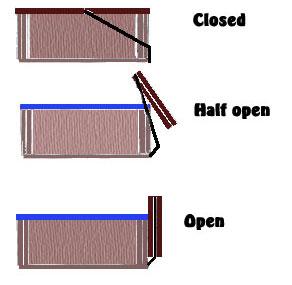

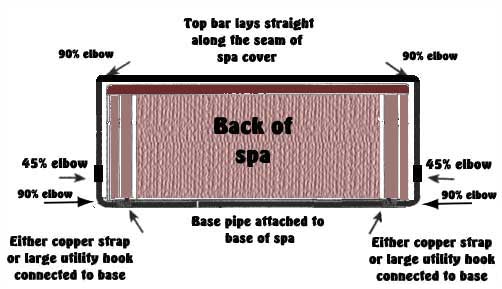

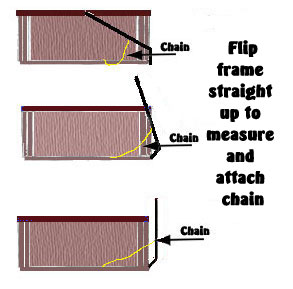

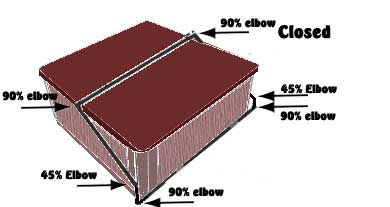

The basic idea here is a modified square of copper pipe that attaches to the rear base of the hot tub and then lays across the seam in the middle of the hot tub cover. When you fold the cover back over the lengthwise piece of pipe, you capture it in the fold. That acts as a kind of hanger for the cover, like a large stiff cloths line.

The basic idea here is a modified square of copper pipe that attaches to the rear base of the hot tub and then lays across the seam in the middle of the hot tub cover. When you fold the cover back over the lengthwise piece of pipe, you capture it in the fold. That acts as a kind of hanger for the cover, like a large stiff cloths line. Cut 2 pieces of 3/4" copper plumbing pipe to that length.

Cut 2 pieces of 3/4" copper plumbing pipe to that length.

Pictures of the finished product |